1.888.302.4875

ECS Eclipse News Archives February 2012

Double Wall Piping Nightmare

February 29, 2012 (comments: 0)

Have you ever really taken a close look at the interstice space of a double wall flex pipe? It’s real tiny isn’t it? Did you ever wonder how long it takes for product to travel thru that interstice space? I did. So I inquired. My research found as an example that the interstice volume is only 0.00246 Vol/Ft on one manufactures flex line. If the run of pipe is 100’, the total interstice volume is 0.246. The information that I obtained, indicates that the amount of time that it takes for product to move that distance based on a typical 1/8 inch pitch per foot would be 1.29 hours.

So you have this scenario; There is 100’ of DW flex piping buried from the tank pad to the dispenser islands. The piping is properly pitched at 1/8 minimum per foot. You have a sensor in the STP sump back at the tank pad. There is no sensor in the dispenser pan. You are relying on the sensor in the STP sump to notify you in the event of a leak because….. you have DW piping with interstitial monitoring. You still with me? The meter under one of your dispensers just blew a gasket and is now leaking. It’s dripping out of that meter at 2 GPH. But, under line pressure, this gasket blows out and the line is pumping at 27psi. Your mechanical leak detector in the STP sump doesn’t catch this. It only triggers at a catastrophic 3 GPH. But you’re a high pumping station, its noon time and the STP motor is constantly running due to the high demand. There is always one nozzle out of the cradle keeping that STP relay closed sending power to the STP. The mechanical leak detector didn’t even get a chance to run the 3 GPH test. How long do you think it would take to fill a typical 95 gallon dispenser pan at 27psi pumping at approximately 8.5 GPM? How about 11 minutes before it starts flowing out onto the island, over the pad, down the driveway, into the street, into a storm drain and into the local river. Liquid takes the path of least resistance. The product didn’t have enough time to make it from the dispenser pan to the STP sensor to trigger an alarm. Not in the 1.29 hours it would take for the product to start dripping into the STP sump. But, you tell me you have a fast thinking attendant monitoring your service station. He immediately hits the emergency stop button. This interrupted the power to the dispensers and will shut down the handle switch signal pulling in the STP relay. Phew! Major crisis averted, still a clean-up needs to occur - But wait, the relay is stuck closed. The power is still going to the STP – product is still flowing. HELP!

Your worst nightmare just came true. What do you do? Well for starters, before this scenario or something like it happens to you, install dispenser pan sensors under your dispensers. There is already a requirement from some states for continuous monitoring of the dispenser pan for product loss on new and substantially upgraded systems. And by continuous monitoring the intent of these regulations is to have a dispenser pan sensor located under the dispenser. Connecting the dispenser sump to a monitored tank top sump just doesn’t cut it. If you had a sensor in the dispenser pan, it would have triggered an alarm notifying you of an issue. The site attendant would then have time to investigate before the worst occurred.

You might want to also put into place a weekly visual check of the dispenser interior. This means opening the dispenser skirt and checking the components and piping. This way you may be able to identify any potential future issues, like weeping fittings or leaking meters and filters. You can then be proactive on resolving any problems before they occur.

Third party management with remote monitoring of the automatic tank gauging systems is just one of ECS Eclipse’s specialties. We can take the headaches away. Please call for more information.

-Lorenzo DiBacco, Field Services Manager

Fuel Theft & Remote Monitoring - Why the two go hand in hand

February 24, 2012 (comments: 0)

Fuel theft in the US reach as high as $8 Billion per year

Fuel prices rising by as much as 20% on an annual basis has encouraged and spurred on petroleum wet stock theft from gas stations and truck stops.

This crime is now costing the United States billions of dollars per year according to industry statistics.

The rate of fuel theft is accelerating as climbing fuel prices tempt more and more people and even employees to steal gasoline, diesel and even heating oil.

We all know that gas is getting pretty expensive. Industry experts predict by spring, gas prices will probably be on average $4.00 per gallon and as much as 5 bucks per gallon later this year.

Because of this hikes in gas prices some people are taking an extreme route to save money.

Tuesday February 21, 2012 at 1am in Hillsborough County Florida a van pulled into a local BP station and attempted to steal gasoline from the underground storage tanks into their vehicle.

After some time the thieves left the scene leaving behind several hundred gallons of gasoline in the vehicle as well as spilling gasoline on the station parking lot.

So, could this happen to you? Or more importantly, is it already happening. At your site after hours ( even during business hours)? Are you protected from fuel theft??

How can you protect from something like this? Open your station 24 hours? What about monitoring of your system?

These thefts occur more often than you would realize and ECS Eclipse has found a way to help, just like ADT we monitor your system.

Our constant fuel monitoring systems manned by a 24x7 team of analysts will protect your valuable wet stock inventory as well as give you peace of mind.

The ECS Eclipse Fuel Management Systems and 24x7 team monitors facilities throughout the United States protecting your assets.

We strive to be your peace of mind, to be your eyes and ears to your underground storage tanks, you may not be able at all times but we can!

To see more about this Florida Theft visit: http://www.baynews9.com/article/news/2012/february/385096/Thieves-attempt-to-steal-hundreds-of-gallons-of-gas

To find out more about ECS Eclipse’s Wet Stock Remote Monitoring visit: http://www.ecseclipse.com/facility-remote-monitoring.html

-Victoria DiBacco, Compliance Analyst

Rhode Island Single-Walled UST systems Removal Deadline

February 17, 2012 (comments: 0)

Owners or of a single-walled UST system in Rhode Island, should be aware that a deadline for permanent closure of these systems may apply to their facility, depending on date of install.

This deadline applies to single-walled tanks and piping installed before May 8, 1985. The most recent Rhode Island Underground Storage Tank Regulations, which were effective on April 21, 2011, actually extended the mandatory closure date by two years, to December 22, 2017. (Previously, in regulations effective August 2007, the deadline was December 22, 2015.)

The 2011 regulations state:

Mandatory Deadline for Permanent Closure of Single-Walled UST Systems (Tanks and/or Piping): Except as provided in Rule 8.01, all existing tank and piping systems without secondary containment shall be permanently closed as follows:

(A) Single-walled tanks and/or piping installed prior to May 8, 1985 shall be permanently closed by December 22, 2017.

(B) Single-walled tanks and/or piping installed between May 8, 1985 and July 20, 1992 shall be permanently closed within thirty-two (32) years of the date of installation.

The exemption mentioned above (in Rule 8.01) refers to systems that store heating oil that is consumed on site for heating purposes. As stated in the rule, single-walled tanks and piping installed after May 8, 1985, must be permanently closed within 32 years from install date.

In order to permanently close a UST, the required steps of the regulations must be followed, which include submitting a closure application and application fees. Generally, “permanent closure” will mean removal of the UST. However, in certain instances, the agency may approve closure in place, rather than removal. In order to get approval, an owner or operator would need to show that specific circumstances at the location would make the excavation involved with removal a poor choice. For instance, if removal would compromise the integrity of a building or could negatively impact a sensitive environmental area, then the DEM may determine closure in place is the better option.

To read the full rule about the deadline for closure of single-walled systems, 8.04 of the UST regulations, follow this link:

http://www.dem.ri.gov/pubs/regs/regs/waste/ustreg11.pdf

- Megan Kazmierczak, Senior Compliance Manager

EPA Strengthening 1988 Regulations

February 14, 2012 (comments: 0)

Are you ready for new UST Rules ?

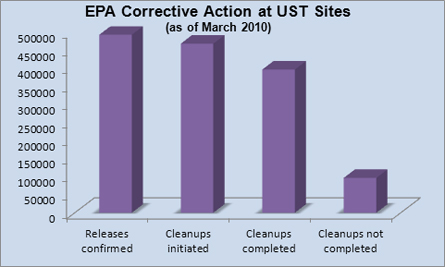

Are you aware that the first time since federal regulations regarding underground storage tanks (USTs) were first promulgated in 1988, the United States Environmental Protection Agency (EPA) is proposing significant changes and additions to these regulations? The proposed rulemaking includes new requirements for USTs primarily focusing on proper operation and maintenance, training, additional release detection requirements and testing of secondary systems and spill prevention.

EPA’s intent for the new rulemaking revisions will allow for improved detection and prevention of UST releases to the environment.

The proposed changes will be significant to the retail motor vehicle, commercial and manufacturing sectors who own and operate USTs if they become effective.

From a practical standpoint, owners and operators of tanks in the vast majority of states with approved UST programs may ultimately see changes in state regulations.

States currently operating under an approved UST program will have three years to submit a revised program approval package to conform to the new regulations. Therefore, if the proposed regulations become effective, owners and operators of USTs should monitor changes to state programs closely.

If you would like to provide comments to EPA concerning these changes, you should submit right now.

You can submit via www.regulations.gov and reference Docket ID No. EPA-HQ-UST-2011-0301.

Frankly, I personally believe we’ve been long overdue (24 years!) for a change in the regulations. Given new technologies and types of UST equipment, as well as fuels compatibilities issues and frankly a poor track record of monthly release detection to identify and allow for operators to react, investigate potential releases, the new rules will allow for “belt and suspenders” to the challenge of preventing releases. Anyways, that’s my personally opinion. On the flip side, this will probably have an impact on your annual operating costs to your facility. One way to look at it though is that releases are very costly and another way to look at it is “an ounce of prevention is worth a pound of cure”. Your facility is valuable. Why not protect it?

Here are the key elements of the new rules under proposal

A. Changes To Establish Federal Requirements For Operator Training And Secondary Containment

1. Operator Training

2. Secondary Containment

B. Additional Requirements For Operation And Maintenance

1. Walkthrough Inspections

2. Spill Prevention Equipment Tests

3. Overfill Prevention Equipment Tests

4. Secondary Containment Tests

5. Operation And Maintenance Requirements For Release Detection Equipment

C. Addressing Deferrals

1. Emergency Power Generator UST Systems

2. Airport Hydrant Fuel Distribution Systems

3. UST Systems With Field-Constructed Tanks

4. Wastewater Treatment Tank Systems

5. Maintain Deferral For USTs Containing Radioactive Material And Emergency Generator UST Systems At Nuclear Power Generation Facilities Regulated By The Nuclear Regulatory Commission

D. Other Changes

1. Changes To Overfill Prevention Equipment Requirements

2. Internal Linings That Fail The Periodic Lining Inspection And Cannot Be Repaired

3. Notification Requirements

4. Alternative Fuels And Compatibility

5. Improving Repairs

6. Phase Out Vapor Monitoring And Groundwater Monitoring As Release Detection Methods

7. Interstitial Monitoring Results, Including Interstitial Alarms

-Joel Hershey, Director of ECS Eclipse Services

CT DEEP UST Petroleum Cleanup Program revocation

February 9, 2012 (comments: 0)

Connecticut’s Underground Storage Tank Petroleum Cleanup Program is in danger of loosing their approval from the EPA as a mechanism of financial responsibility. The program was created to serve as an alternative to private insurance to gas station owners who could not get insurance through the private sector.

Currently the state owes more then $17 million dollars to businesses who have received approval to be reimbursed for cleanup costs, and more then $81.6 million worth of applications for reimbursement.

Due to state cutbacks and troubling economic times the fund has lost much of its state funding. "At current funding levels, most owners and operators will not receive reimbursement in their lifetime," James T. Owens III, director of the EPA's Office of Site Remediation and Restoration, wrote to state Environmental Protection officials. "Clearly, in its current condition, the use of the state fund as a means of financial responsibility does not encourage -- or in some cases enable -- releases to be addressed promptly."

January 26, 2012 the EPA sent a letter to Bureau of Water Protection and Land Reuse Chief Betsey Wingfield stating “EPA will begin the process of withdrawing approval of the CT DEEP Program state fund as a mechanism of financial responsibility should a solution not be achieved by the end of the legislative session on May 9, 2012.”

If the state can not find a solution by May 9th and the EPA ends its recognition of the program, gas stations across the state will be forced to find private insurance, with the high costs these station owners will be forced to raise prices or to close down completely.

-Victoria DiBacco, Complaince Analyst

Recent Field Inspection

February 8, 2012 (comments: 0)

During a recent inspection, I had been informed by site personal of an on-going issue of intermittent sensor alarms. The location was having a difficult time determining the cause of the alarms and also meeting the monthly requirements for documentation of continuous interstitial tank monitoring. What I found was the interstitial sensor cable was being pinched by the steel 18 inch manway cover. It appears that upon installation the riser was installed at such a height that over time when the concrete tank pad settled just a little, that the wire ended up being pinched by the manway cover causing the intermittent alarms. The internal wire was found to have been partially broken under the outer jacket, while the outer jacket remained continuous. A shortening of the riser and repair of the sensor cabling corrected the issue and the site is now back in compliance.

Lorenzo DiBacco, Field Services Manager

Post Tags

- 24/7

- alarms

- ATG

- ATG monitoring

- August 8 2012

- Automatic tank gauge

- buying a convenience store

- Buying Station

- Cleanup Fund

- Cleanup Program

- Compliance

- compliance audits

- Connecticut

- construction

- credit card

- CT

- Decommissioning

- DEEP

- Dispensers

- Double Wall piping

- Draft UST Regulations

- DW Piping

- EPA

- Ethanol

- Facility Compliance

- facility inspections

- Fuel Spill

- Fuel Theft

- gasoline

- Gas Station

- Gas Station Inspections

- gas station tanks

- Identity Theft

- Independent Oil Marketers Association

- Inspection

- inspections

- interstitial monitoring

- inventory reconciliation

- IOMA

- MA

- MA DEP

- manways

- Massachusetts

- MA UST

- MA UST Regulations

- NH UST Regulations

- Notice of Violations

- NOV

- NOV's

- Ohio

- Operator Training

- Organization

- permanent tank closure

- Petroleum

- Recordkeeping

- Regulations

- release detection

- remote monitoring

- Rhode Island

- secondary containment

- Selling a convenience store

- Selling Station

- sensors

- Shear Valve

- single wall tanks

- Single wall ust closure

- Spill Bucket

- Stage II

- Stage II Decommissioning

- Stage II Vapor Recovery

- State Fund

- State Regulations

- storage tanks

- SW Closure

- tank regulations

- Tightness Testing

- underground piping

- underground storage tank

- Underground Storage Tank Regulations

- underground storage tanks

- UST

- UST's

- UST Compliance

- UST Inspections

- UST Operator Training

- UST paperwork

- UST Regulations

- UST removals

- UST Rules

- UST Training